Your Questions Answered: A Deep Dive into the New PhoXi 3D Scanner Gen3

Following the launch of our PhoXi 3D Scanner Gen3, we were excited by the wave of insightful questions from our community during our live Q&A session. This new generation represents a leap forward in performance, accuracy, and scanning time, and you had some fantastic questions about its capabilities.

We’ve compiled and transcribed the key questions and answers from the event to provide a detailed resource for everyone.

Let’s dive in!

Generation 3: The Core Upgrades

Q: What are the differences in physical dimensions between Gen2 and Gen3?

To unify the form factor across our product lines, the new PhoXi 3D Scanner Gen3 is approximately 11 millimeters longer than the Gen2 models. This change applies to all sizes (S, M, L, XL). Importantly, this slight increase in length is already accounted for in the designs of our partners’ protective enclosures, so the new generation still fits perfectly.

Q: How has the accuracy improved with Gen3?

This is a multi-faceted improvement. While the fundamental depth accuracy remains in a similar range to the previous generation, the overall quality and usefulness of the data have been massively enhanced.

Ultimately, you get a much richer, more detailed, and cleaner point cloud for more robust and reliable applications.

The key improvements are:

- Higher Resolution: With a 5MP sensor, we provide 60% more 3D points for every scan.

- Greater Detail & Fidelity: The combination of higher pixel density and the new blue laser technology results in scans with significantly more detail, higher fidelity, and less noise.

Q: What do I need to consider when transitioning from a Gen2 to a Gen3 scanner?

We’ve made this transition as smooth as possible. We understand the need for consistency in established projects and system replicas.

PhoXi 3D Scanner Gen3 Compatibility:

- PhoXi Control: Required version 1.16 or higher.

- PhoXi API: Applications must be built with API version 1.16 or higher to utilize new features.

- Bin Picking Studio: Required version 1.11 or higher.

- PhoXi 3D Scanner Gen3 is 11mm wider than PhoXi 3D Scanner Gen2

Performance in Challenging Conditions

Q: How would the sensor perform on liquid molten metal at 800∘C to continuously measure volume?

For scanning moving objects like pouring molten metal, our best guess for a feasibility would be the MotionCam-3D as it allows for scanning of static as well as dynamic objects.

Critically, our new blue laser projection unit, available for both product lines, is ideal for high-temperature applications. Hot metal at 800∘C emits strongly in the infrared and red spectrums.

The blue spectrum is much less affected, allowing our sensors to capture a strong, clean signal and produce highly accurate point clouds. We have successfully scanned objects at temperatures up to 1200∘C.

Shortly before releasing PhoXi 3D Scanner Gen3, we also launched a new generation of our flagship 3D camera – MotionCam-3D Color (Blue). While PhoXi 3D Scanner excels at high-accuracy static scenes, MotionCam-3D unlocks possibilities for dynamic scanning in motion (up to 144 km/h). Here you can explore its fit for your applications:

Q: How does the device perform in extreme heat or cold?

The standard operating temperature for the PhoXi 3D Scanner is 0∘C to 40∘C. For environments outside this range, we partner with suppliers to provide specialized protective casings. These enclosures can create a controlled atmosphere inside, enabling the scanner to operate in extreme conditions.

We have successful customer applications ranging from scanning hot metal shrouds at over 1000∘C to depalletizing in freezers at −16∘C, and even guiding underwater welding robots!

Q: How can you keep the sensors cool in a hot environment of 100∘C?

For any conditions outside operating range—hot or cold—we work with an external supplier who provides specialized protective enclosures. These housings shield the device and can be equipped with external vortex coolers or heaters to maintain the optimal operating temperature inside.

We have many successful use cases in extreme environments, including:

- Robot guidance for picking hot metal shrouds in enormous ambient heat.

- Depalletizing frozen goods in a −16∘C freezer.

Q: Can we scan objects that are extremely hot, like metal slabs at 1000∘C?

Yes, you can. This is a major strength of our new blue laser technology. A glowing hot object is essentially its own source of intense ambient light. Our system excels here for two reasons:

- Blue Laser: The blue laser’s wavelength is far away from the red and infrared spectrum where the hot metal is glowing most intensely.

- Ambient Light Suppression: Our powerful algorithms treat the glow from the object itself as ambient light and effectively filter it out, allowing the PhoXi 3D Scanner to clearly see the projected laser pattern.

Multi-Scanner Setups & Calibration

Q: How many devices can be used at once in a multi-view setup?

If the scanners’ fields of view are fully overlapping, the natural limit is two devices: one using a red laser and one using a blue laser. This prevents interference between the structured light patterns.

However, for larger scenes where fields of view only partially overlap or are adjacent, you can use as many scanners as required in an alternating pattern (e.g., blue, red, blue, red).

Furthermore, all our sensors feature a hardware trigger that allows you to “daisy chain” multiple devices. This lets you trigger the devices in a desired sequence in such a short period that it’s virtually instantaneous for most applications.

Q: How are scanners aligned, and is processing done on the camera or an external PC?

We offer several ways to align, or “cross-calibrate,” multiple sensors:

- Marker Boards: This is the simplest method. By showing a calibration marker board to both sensors, they can automatically calculate their relative positions and output data in a shared coordinate system.

- 3D Calibration Objects: Alternatively, customers use custom 3D objects as a shared reference point.

Once calibrated using marker boards, the transformation is stored on the devices. This means the scanners themselves handle the alignment and output point clouds in a shared coordinate system, requiring no external PC for this step.

For more advanced tasks like merging the point clouds from multiple sensors into a single 3D mesh, an external PC running software like Photoneo 3D Meshing is required.

Software, Workflow, and Applications

Q: I want to scan an object and compare it to its CAD model. Can you help with that?

Yes, absolutely. This is a very common inspection application. Our scanners are compatible with leading machine vision software, including Zebra’s Aurora™ Vision Studio and third-party packages like Halcon.

The typical workflow involves aligning the captured point cloud with the reference CAD model or a “golden sample” scan.

The software can then subtract the two and create a heat map to visualize any deviations or defects, showing exactly where and by how much the scanned part differs from the ideal model.

Q: Can you do localization on a part that has no CAD model, but has known features from a 2D drawing?

While you can’t use a 2D drawing directly for 3D localization, we have two excellent solutions:

- Create a 3D Model: Use the part itself to create a digital model. With our Photoneo 3D Meshing software, you can generate a high-quality 3D model of your object in seconds, which you can then use for localization.

- AI-Based Localization: You can train a neural network to recognize and locate the part based on a series of annotated scans. This powerful method doesn’t require a CAD model at all.

Generation 3 Specifics & Logistics

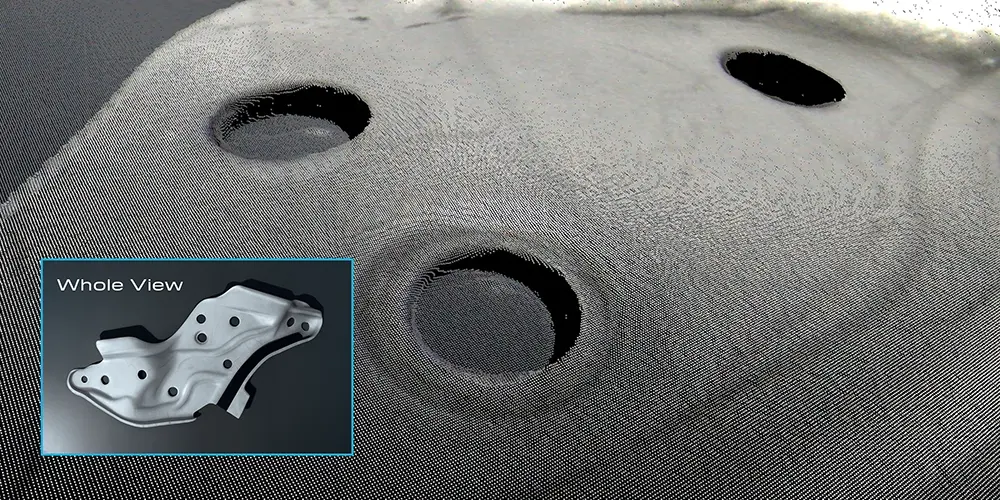

Q: Are the physical dimensions and mounting points different for Gen3?

The dimensions are very similar. The Gen3 body is approximately 11 mm longer. However, it still fits within existing mounting spaces and the protective enclosures designed for the previous generation.

Q: What about laser safety for the new blue laser?

Like our red laser models, the new blue laser scanners are available in eye-safe Laser Class 2 and Class 3R. Thanks to the efficiency and power of the new projection unit, the blue Laser Class 2 model delivers performance comparable to the previous generation’s red Laser Class 3R, offering a powerful and safe option for more applications.

Q: When will the PhoXi 3D Scanner Gen3 be available?

We are accepting orders right now! The first production units are scheduled to be ready for delivery in September 2025.

Q: What’s the best way to ask questions about our specific application?

We’re always here to help! The best way to start a discussion about your unique project is to contact our team. You can reach out to your local distributor or email us directly at photoneo-sales@zebra.com or photoneo-sales-us@zebra.com

You can re-watch the full launch webinar here; ai.photoneo.com/best-3d-scanner